Product

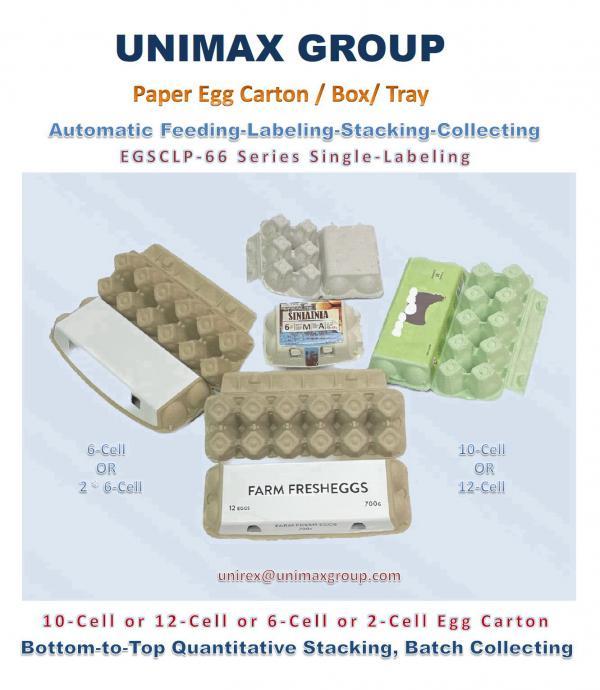

EGSCLP-66 Automatic Paper Pulp Egg Carton Labeling Machine

Product ID: Paper Pulp Egg Carton Labeling EGSCLP-66 Series (163)

■ Application:

- For 10 or 12-cell

- Optional system for 6-cell or 2*6-cell egg carton

- Precut Paper Label

- Wet Adhesive Water Base Cold Glue Type

■ Designed /Operation Speed:

• EGSCLP-66S: Approx. 25 ~ 30 / 20 ~ 25 Pieces/Min.

• EGSCLP-66M Approx. 25 ~ 30 / 22 ~ 28 Pieces/Min.

♦ Egg Cartons Supplemental Filling in Stack-Hopper

- No Need to Stop The Machine.

Specifications:

■ Function & Specification:

- Equipped with Automatic Feeding-Labeling-Collecting System

- Accurate Cam Drive Labeling System

- Batched Quantity Labeled Carton Automatic Stacking

- Equivalent Quantity Labeled Carton Bulk Collecting System

- Egg Carton Specification Fixed Type

- Interchangeable Stack-Hopper System

- Series-S for 6-cell or 10-cell or 12-cell Egg Carton

- Series-M for 10-cell or 12-cell Egg Carton

- Series-M Optional for 6-cell or 2*6-cell Egg Carton

- Multi-Application Type Depend on Egg Carton Specification.

- Label Size: Max. 250 (W) x 150 MM (L = Label gluing direction)

Features:

■ Features:

1). Using general water base cold glue

- Easy for operation,maintenance and easy getting glue suppliers.

2). Integrated control egg carton labeling and feeding-collecting.

3). Single-Stack-Hopper magazine easy for preparing egg cartons - Top-to-Bottom for labeling operation.

4). Precise labeling system by Cam drive system

5). Main Labeling Machine * 1 Set

• EGSCLP-66S: 1-Stage peel-off & taking system

• EGDCLP-66M: 2-Stage peel-off & taking system

6). Egg cartons separated and taking from stack-hopper magazine

on to conveyor automatically.

7). Egg cartons put onto conveyor & set position automatically.

8). Twin-pressing system for 3-face (top-front-hinge sides) labeling.

9). Servo control transporting conveyor system.

10). Labeled product lift-stacking into collecting stack-hopper

- Bottom-to-Top automatically.

♦ Collecting of egg cartons no need to stop the machine.

■ Control System:

• Gluing System: Accurate Cam Drive Roller Gluing

• Labeling: X-Table Robot & Servo Control

• Japan ‘MITSUBISHI’ PLC programmable logic control system

• Japan ‘YASKAWA’ Servo Motor system.

• Japan "PROFACE" Touch Screen Monitor control system

* The brand names of products shown in the catalogue are the reference application to our manufacturing equipment only.

Order Information:

- Minimum Order: Negotiable

- Branded Product

Contact Detail

| CEO: | Mr. F. Y. Lu |

| Contact: | Sales Department |

| Head Office: | 12th FL-4, No. 201, Fu-Shing North Road, Taipei 10596, Taiwan |

| TEL: | 886-2-87126099 (Rep.) |

| FAX: | 886-2-87126096 (Rep.) |

| Email: | unirex@unimaxgroup.com |

| URL: | http://www.unimaxgroup.com http://www.unimaxgroup.com.tw |

| ZIP: | 10596 |

Hot Products

UC-228 Automatic Inter-Fold Tissue Conve...

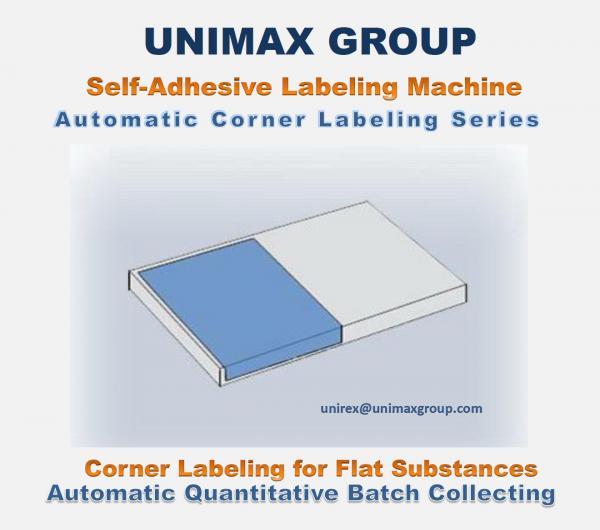

610E-K2-AFC-S1 Corner Labeling Machine

Automatic Corner Labeling Machines

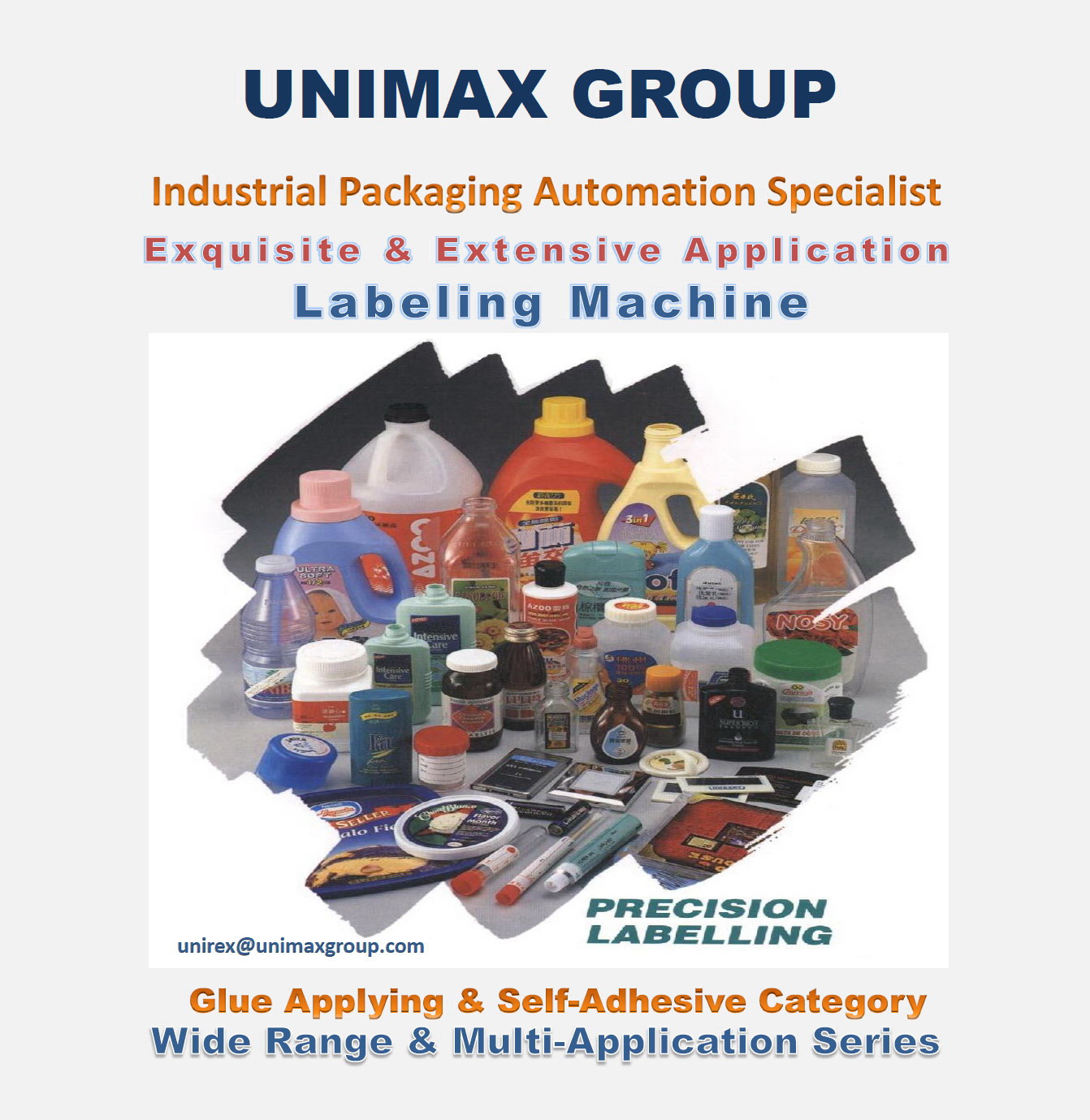

Self-Adhesive and Glue Applying Labelin...

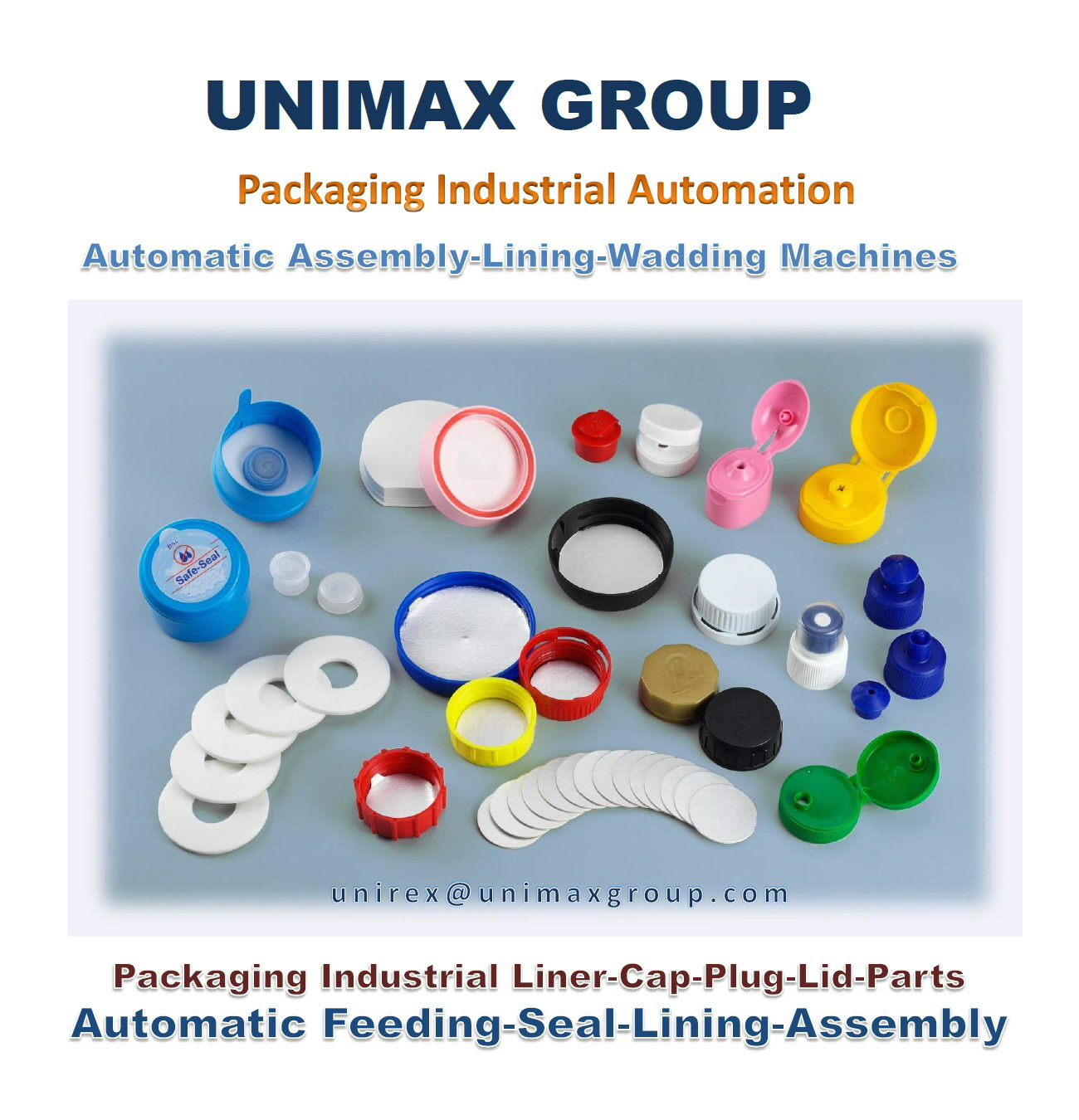

Assembly-Lining-Wadding Machines

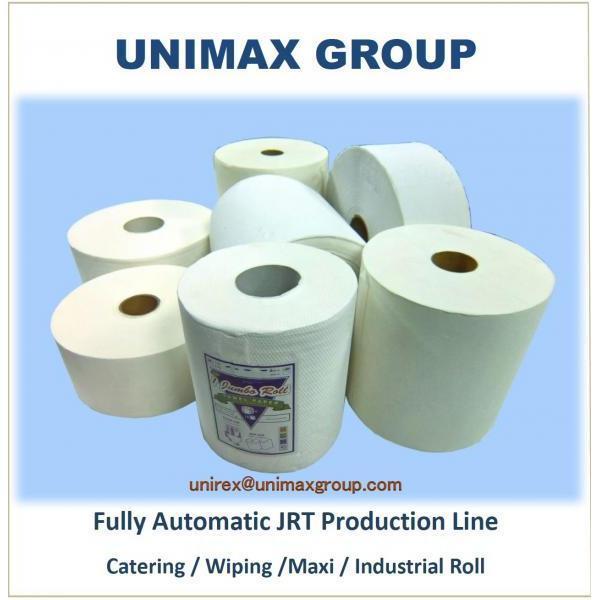

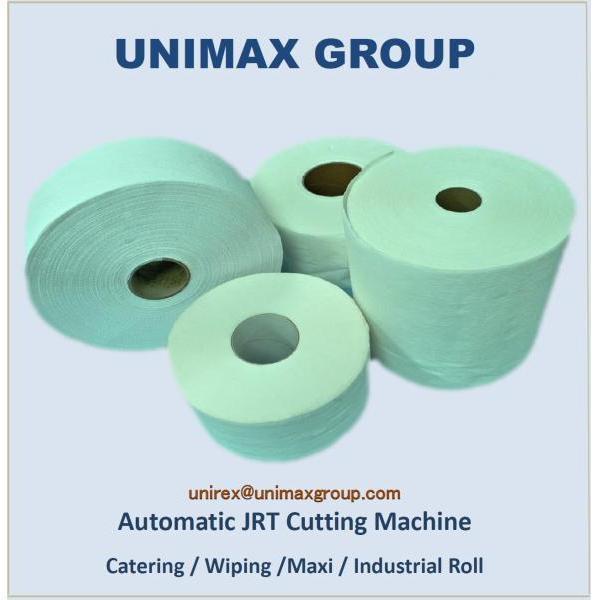

Fully Automatic Maxi/Catering/Wiping/Ind...

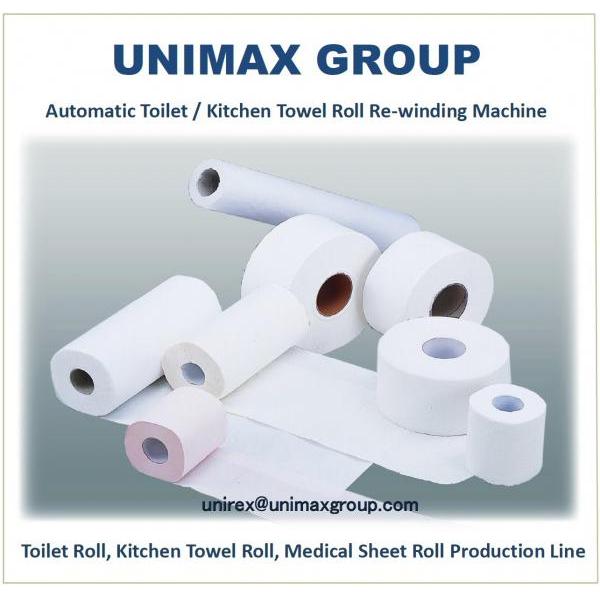

UC-1121 Automatic Toilet / Kitchen Towel...

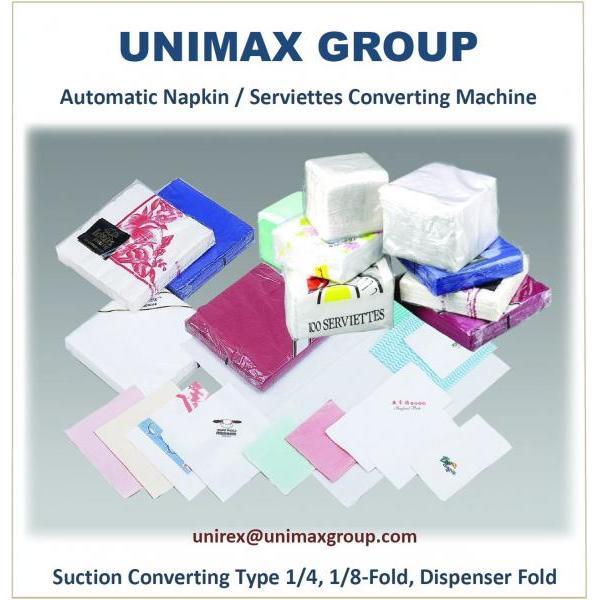

US-234-A Suction Type Tissue Paper Napki...

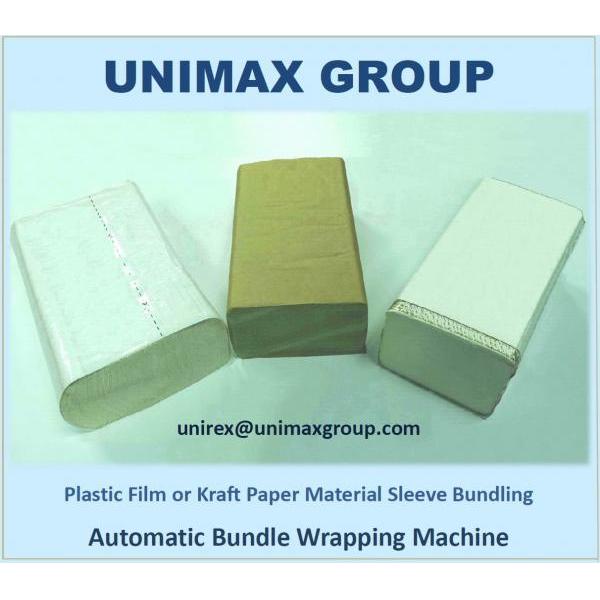

UC-286-SV1Tissue Paper Log Sleeve Bundl...

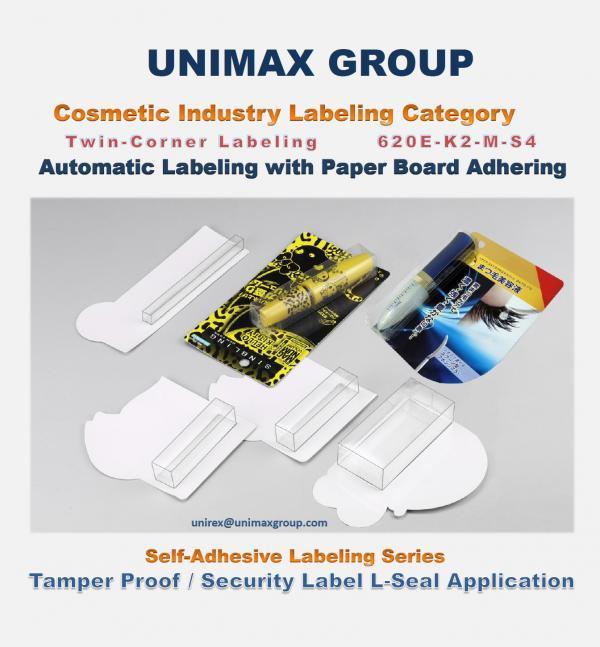

620 E-K2-M-S4 Cosmetic Box Security Stri...

UC-230-AB Maxi/Industrial Roll Fully Aut...

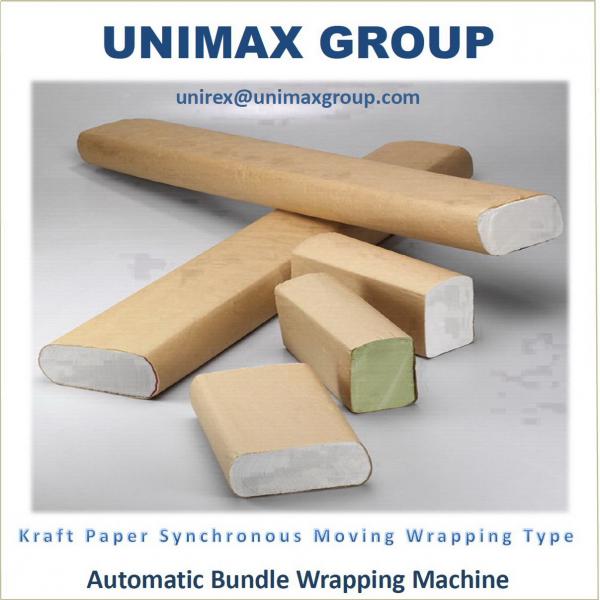

UC-286-SV2 Tissue Paper Sleeve Bundle Wr...