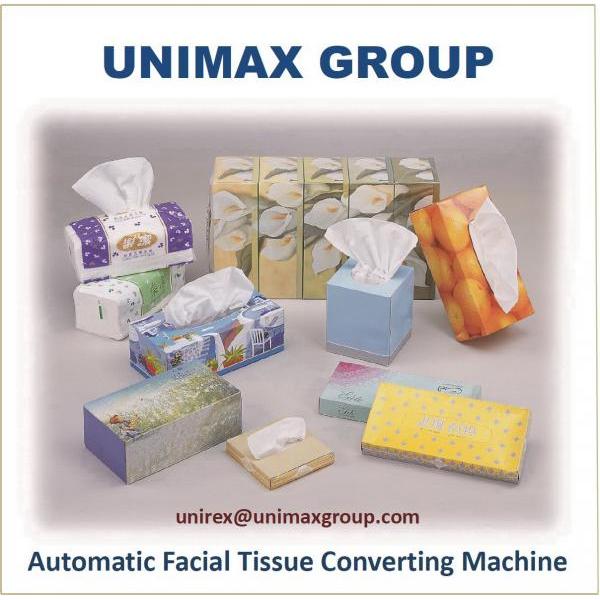

Hot Products

UC-228 Automatic Inter-Fold Tissue Conve...

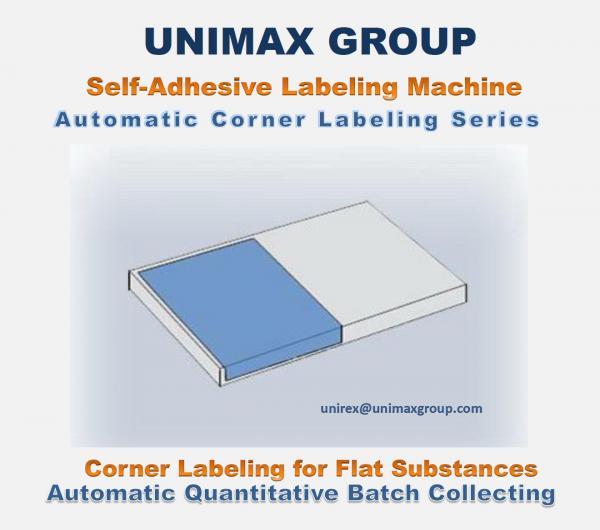

610E-K2-AFC-S1 Corner Labeling Machine

Automatic Corner Labeling Machines

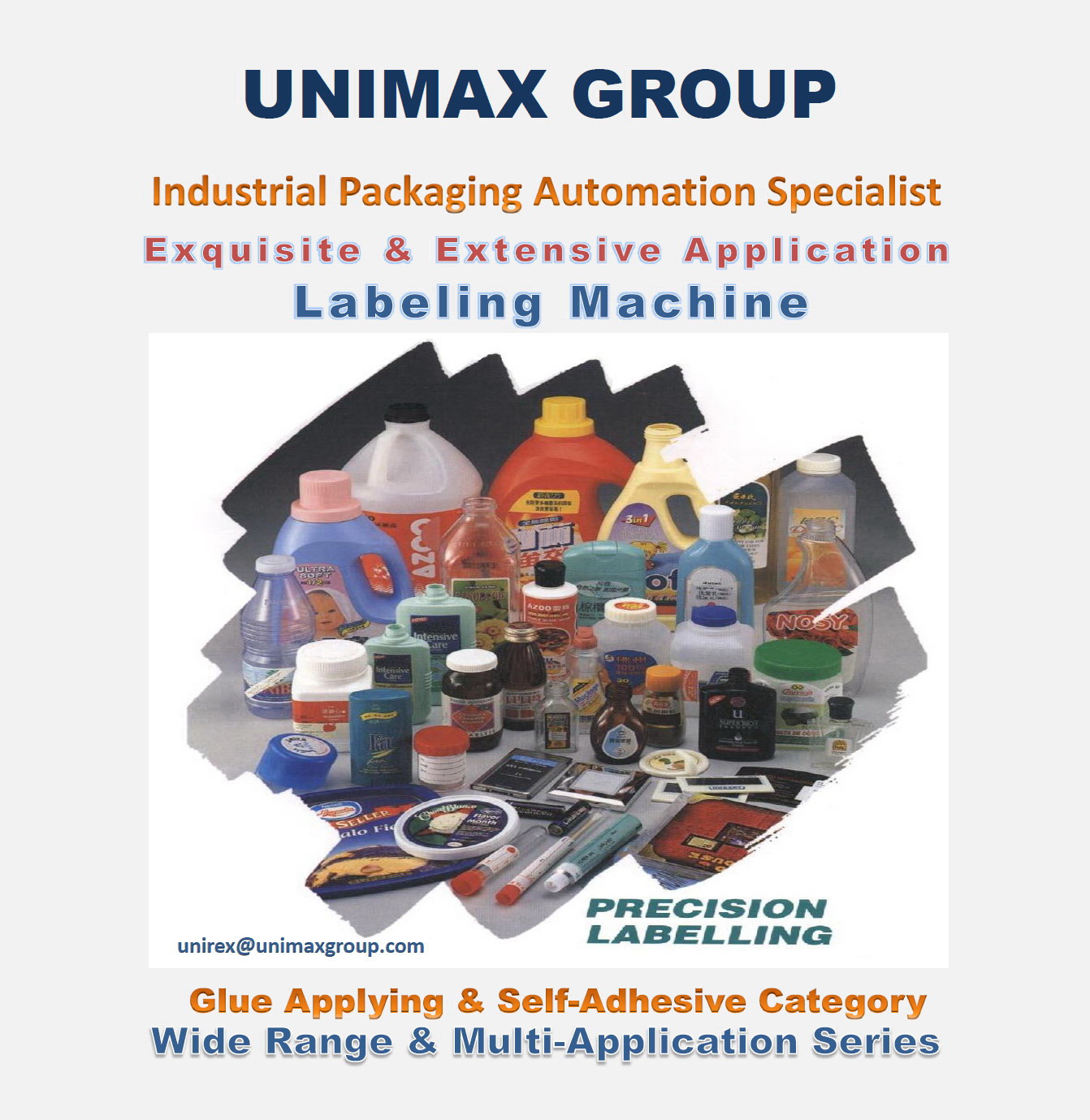

Self-Adhesive and Glue Applying Labelin...

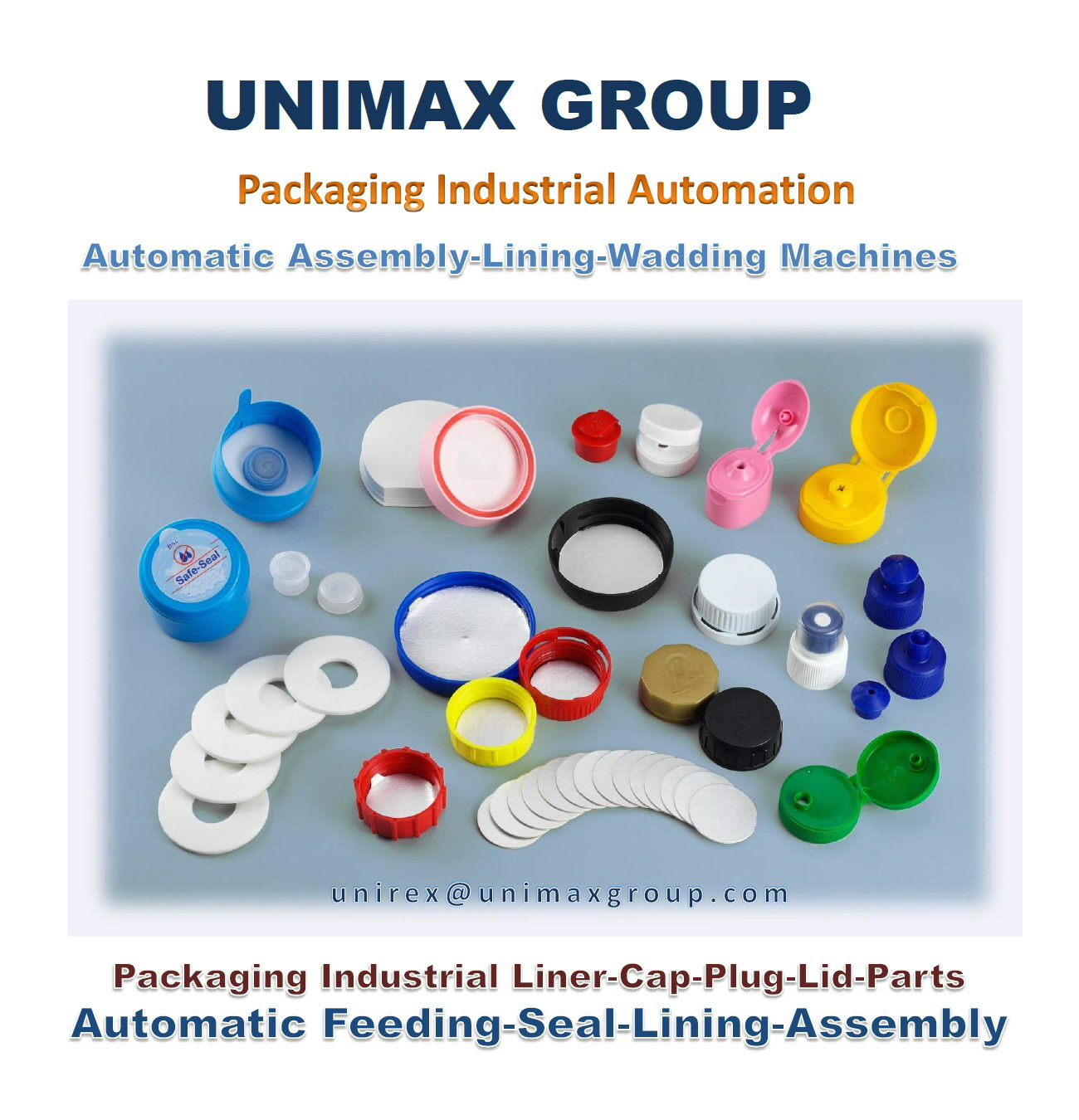

Assembly-Lining-Wadding Machines

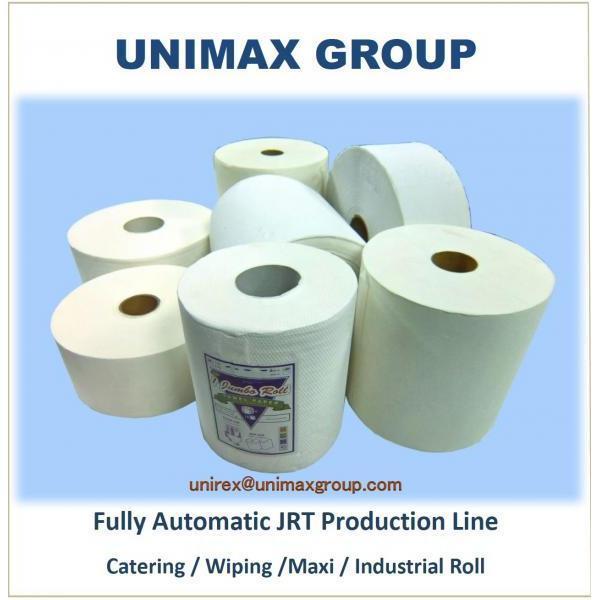

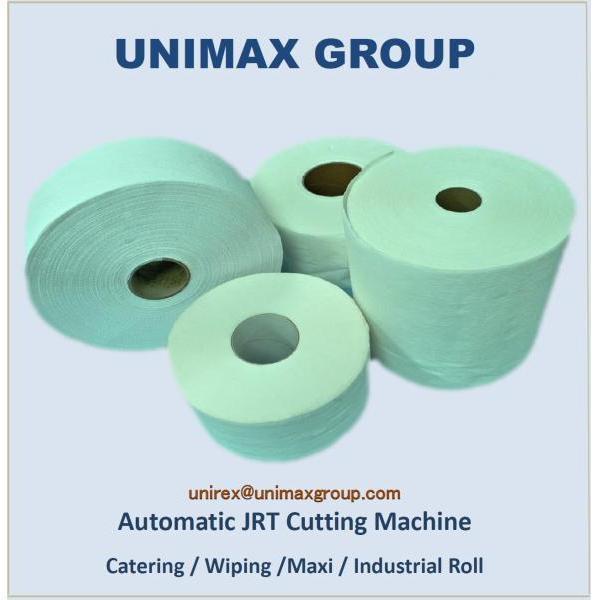

Fully Automatic Maxi/Catering/Wiping/Ind...

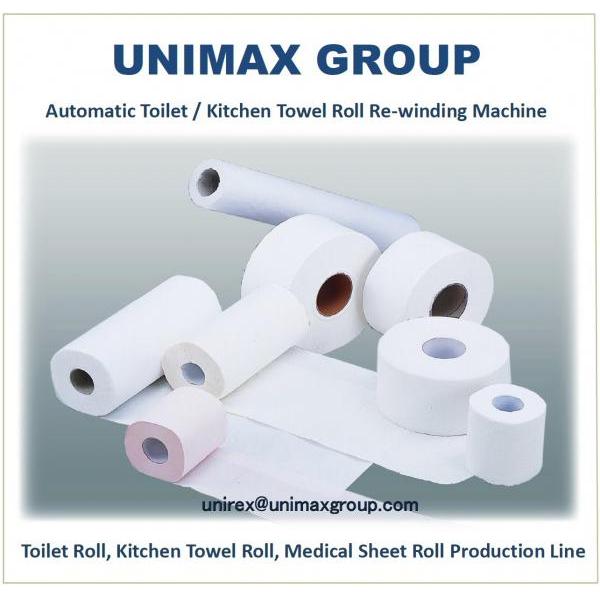

UC-1121 Automatic Toilet / Kitchen Towel...

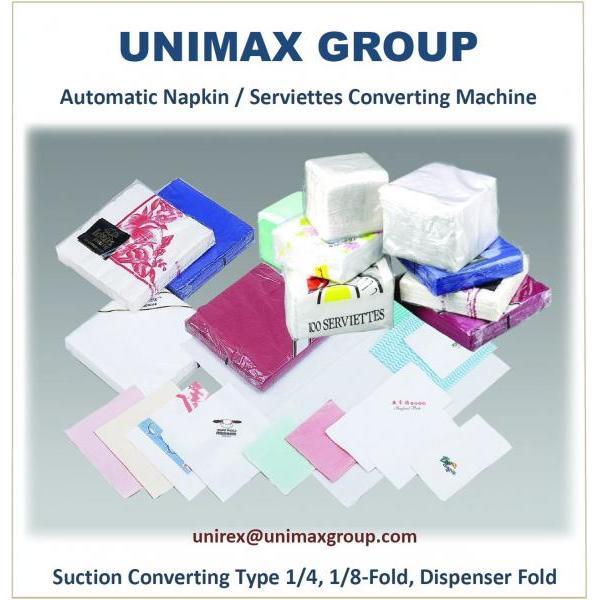

US-234-A Suction Type Tissue Paper Napki...

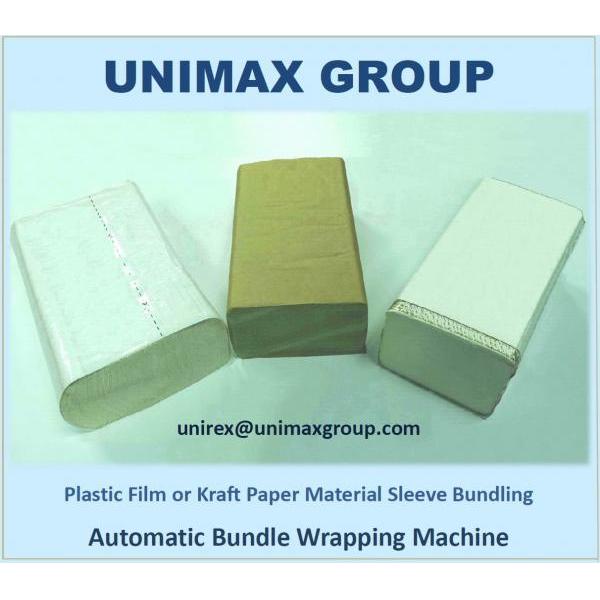

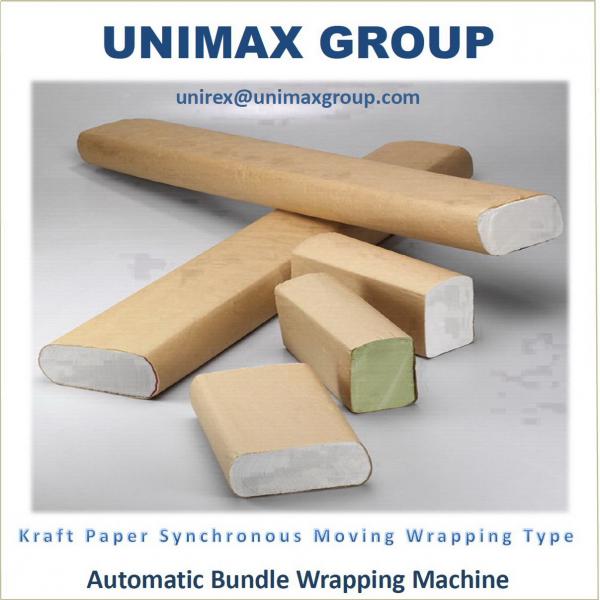

UC-286-SV1Tissue Paper Log Sleeve Bundl...

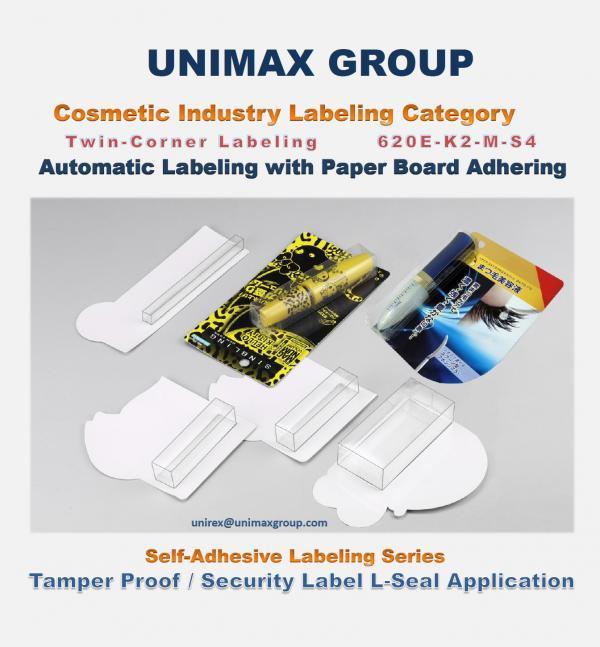

620 E-K2-M-S4 Cosmetic Box Security Stri...

UC-230-AB Maxi/Industrial Roll Fully Aut...

UC-286-SV2 Tissue Paper Sleeve Bundle Wr...